Most days, I don’t find myself wearing any belt, let alone a Six Sigma black belt. I am only an “armchair” Six Sigma observer; I have not spent hours in manufacturing environments learning about Six Sigma.

I do, however, have a curiosity about process improvement, a few good friends who are Six Sigma experts, and a bit of a bent towards statistics. That might be enough to make me dangerous.

It has dawned on me that a whole lot of noise has been brought to the marketplace about the importance of customer experience (CX). Am I the only one who has this feeling that the literature is rich in concern about customer experience, and comprehensive about how to “gather information” related to customer experience, but relatively silent on the practices that will actually improve customer experience?

How can we go from understanding the customer experience to improving customer experience?

I don’t have easy answers. In one recent engagement, after journey mapping the intake and onboarding process of a prototypical new customer, I found myself looking at a complex journey map and muttering “there’s gotta be something better than this.” So I dug in to a collateral challenge, creating a Customer Experience Standards Guide. That was an informative and interesting exercise, but I left the customer out there to continue to experience the existing journey without substantial renovation.

Customers still encounter the same steps in the journey, the same bottlenecks even, just a bit friendlier, with a stricter time to service inquiry response from the organization that tries harder now to communicate more effectively and say the right things. That’s nice. Yet it is somewhat less than satisfying.

Six Sigma is a process improvement framework that enjoys a core methodological toolkit, but that is strangely subject to the viewer’s emphasis. In the eyes of the beholder, Six Sigma may be:

- a management philosophy

- a scientific method

- a formal initiative

- applied statistics

- specific tools

- a quality measure

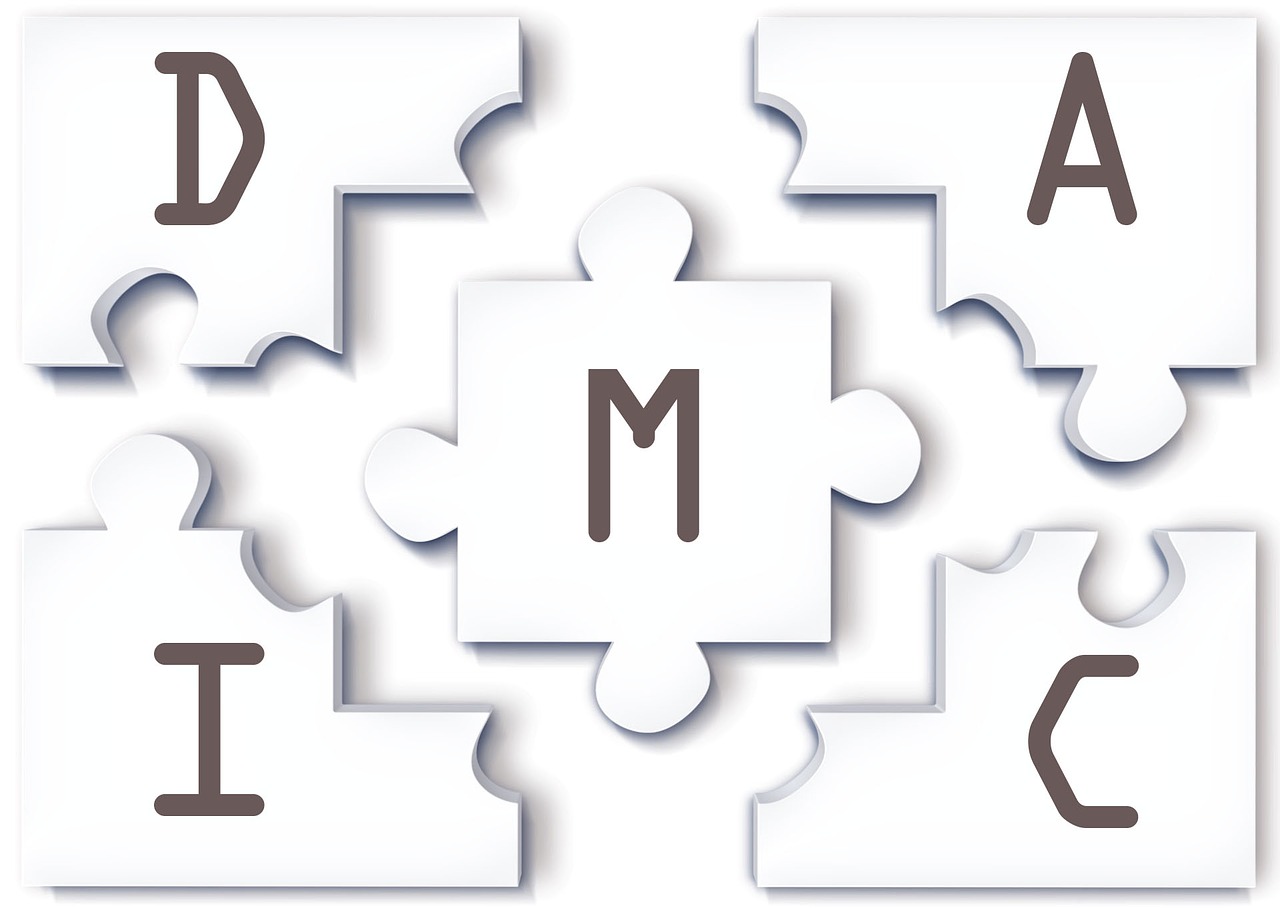

- a five phase process (define, measure, analyze, improve, control – or DMAIC)

Don’t we struggle a bit with actually engineering customer experience change? Applying Six Sigma as a philosophy and methodology to customer experience improvement initiatives makes some sense, because Six Sigma is rooted in five underlying propositions:

- Create value for customers

- Manage on the basis of data and facts

- Analyze cause and effects

- Minimize waste, errors and defects

- Contextualize and facilitate collaboration

The Six Sigma body of tools and knowledge – with DMAIC as a process focus – can help us bring a methodological rigor to improving the customer experience.

Most of us engaged in customer experience engineering are on the path to being good with the M, or Measure, element of Six Sigma. The Measure phase of a Six Sigma project focuses on defects, opportunities, journey mapping, establishing a data collection plan, and identifying process capability (which has a specific definition in the context of Six Sigma, and more depth to it than this short article should cover). There may be more about measurement that the Six Sigma body of knowledge can teach us, but we sure are trying hard, with big data, voice of customer surveys, and more.

But how well are we doing with the other aspects of DMAIC? When we think of the Define aspects of our customer experience “projects,” how well are we doing in defining our goals, establishing a valid and solvable problem, and bringing focus to our efforts? Are we serious enough to draft CX Project Improvement Charters, wherein we define our intentions and those who will be involved? Are we undertaking effective journey mapping? Do we validate our journey maps with hard data and facts from those who have experienced the journey? Do we use tools like fishbone and SIPOC diagrams, and Failure Modes and Effects Analysis (FMEA) to help gain an understanding of (and establish a prioritization for) the processes that are getting in our customers’ ways? A project well defined – with executive endorsement – goes a long way towards problems resolved.

With data in hand – are we performing effective Analysis to seek understanding of variations in the results and in the activities that produced them? Are we looking for cause and effect chains? Can we identify key input variables that, if adjusted, will remedy our CX problem(s)? Are we brave enough to attempt to calculate the cost of poor quality in our customer experience? Are we leveraging CX insight into hypothesis, so that we may move forward to improvement?

Six Sigma focuses on identifying and minimizing variation in processes. Are we using best efforts to separate the important from the unimportant in customer journey interpretation so that we don’t chase windmills?

The big I of DMAIC – Improvement – is the ultimate goal of any efforts expended in customer experience work. Six Sigma encourages choosing targets for improvement with wisdom, formal and informal brainstorming towards a better “way,” selecting a strategy and tactics for an experiment in change, remapping the revised experience, and ensuring that you know how you might fail (and mitigating failure). Importantly, the Six Sigma methodology encourages continuing experimentation – an iterative process – that is monitored for success via clear results measures.

Sadly, people relapse. Existing habits are hard to break, and new (and intentionally improved) habits are hard to build. The Control phase of a Six Sigma project reminds us that gains must be maintained. To do so, change management platforms – including documentation, training, in-process monitoring (and early alerts to deviations), formal response plans before deviations mount, and more – are part of the Six Sigma methodology that can sustain improved CX.

A concern I’ve heard about Six Sigma is that it is very easy to get caught up in project work, measurement and process – and to neglect the people dimension of work. Obviously, as Six Sigma methods are applied to CX, we must respect the very human nature of the customer experience, including both customer and employee contributions to same. Employees who touch customer journeys really need to be allowed to exercise their judgment (because it is a fine balance) against improvements that are intended to minimize “defects.”

I am convinced that the philosophy, intent, methodologies and tools of Six Sigma can be gracefully applied to customer experience improvement engineering. Six Sigma in CX can help us reinvent customer journeys, secure enhanced consistency, and at the same time, create more responsive and more customer-committed organizations.

Author: Todd Kasenberg

Todd Kasenberg is Principal of Guiding Star Communications and Consulting. His long career in marketing and sales led him to question the buying process – and he stumbled down the rabbit hole only to discover customer experience. Todd delivers insight and actionables – all with a curious mixture of intensity and humour – in unfolding the people performance opportunities available to great organizations. He is a software entrepreneur, owning the Journifica (www.journifica.com) customer journey mapping and validation platform.

His love of technological enablement blends nicely with a passion for building better organizations and creating happy in our work and customer experiences. Todd just believes in a constantly bettering world.